|

|

|

|

stevie_o wrote:Loving the effort going in to this to make it informative and useful to all builders, nice work  Steve Just nice to give back some of the little tips i have picked up over the years Jase “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

Rank: Elite       Groups: Registered

Joined: 22/03/2010 Posts: 2,065 Points: 6,295 Location: Gorleston-on-sea

|

Fascinating Jase...Just a point of interest mate...Will you be tiling or going down the polished second planking route for display? Great work!! Loving it!!  Current Builds: Deagostini HMS Victory: Deagostini HMS Sovereign of the seas. Completed Builds: Del Prado: HMAS Bounty: Hachette: RMS Titanic: Del Prado: Cutty Sark...

|

|

|

|

|

jonny7england wrote:Fascinating Jase...Just a point of interest mate...Will you be tiling or going down the polished second planking route for display? Great work!! Loving it!!  I will be copper tiling and talking throug varnising J “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

Rank: Super-Elite        Groups: Registered

Joined: 08/03/2014 Posts: 2,977 Points: 8,523 Location: united kingdom

|

This is a great tutorial, but it just proves to me plastic is easier and far, far less complex, one lesson I learned from my one and only plank on frame build was know which woods to use on the planking I used balsa as my first planking then, ( not following instructions (the kit supplied lime and balsa for planking and you were supposed to use either or, I chose balsa as the first as I thought it would be easier to sand, as I knew the first planking would need a lot of sanding as it was my first attempt(stupidly thought the lime would make the kit stronger so used that as the second) looked ok when I went to bed, when I looked next day the lime had pulled the balsa off the frame anywhere I had sanded the balsa too thin, ( mine never looked as good as this on the first planking) not sure I would ever be upto a kit this complex. Ken's the name modeling's the game.

|

|

|

|

|

kpnuts wrote:This is a great tutorial, but it just proves to me plastic is easier and far, far less complex, one lesson I learned from my one and only plank on frame build was know which woods to use on the planking I used balsa as my first planking then, ( not following instructions (the kit supplied lime and balsa for planking and you were supposed to use either or, I chose balsa as the first as I thought it would be easier to sand, as I knew the first planking would need a lot of sanding as it was my first attempt(stupidly thought the lime would make the kit stronger so used that as the second) looked ok when I went to bed, when I looked next day the lime had pulled the balsa off the frame anywhere I had sanded the balsa too thin, ( mine never looked as good as this on the first planking) not sure I would ever be upto a kit this complex. They can be daunting, and thats why the Part work format works so well as you get it spelled out step by step, a beginner can build a much more complex kit with artwork support than they could without. Glad your enjoying the post  jase “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

|

|

|

|

|

|

|

Yet another brilliant tutorial on planking Jase loving all the tips  Rgd Martyn Building ?

Completed. Soliei Royal . Sovereign of the Seas . Virginia . Scotland . San Felipe . Corel vasa , Santisima Trinadad X section , Vasa

Next Build ?

When sailors have good wine, They think themselves in heaven for the time. John Baltharpe

|

|

|

|

|

Martyn Ingram wrote: Yet another brilliant tutorial on planking Jase loving all the tips  Rgd Martyn Thanks Matey, glad your enjoying the build. Jase “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

Rank: Pro Groups: Registered

Joined: 08/05/2015 Posts: 239 Points: 693 Location: Wisconsin

|

|

|

|

Rank: Master       Groups: Registered

Joined: 08/07/2010 Posts: 1,036 Points: 3,086 Location: Thetford, Norfolk, UK

|

Another great tutorial Jase,I'm learning something new with each post. Especially like the tip to use pins to hold the planks tight against each other while the glue dries.

happy building

David

|

|

|

|

|

RogerThornhill wrote:Amazing work here!! Many thanks for looking in “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

|

|

daffy09 wrote:Another great tutorial Jase,I'm learning something new with each post. Especially like the tip to use pins to hold the planks tight against each other while the glue dries.

happy building

David Glad your getting somthing out of it. Thank you for looking in “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

Rank: Pro Groups: Registered

Joined: 08/05/2015 Posts: 239 Points: 693 Location: Wisconsin

|

I may just have to get this boat - this is such a great tutorial!

|

|

|

|

|

RogerThornhill wrote:I may just have to get this boat - this is such a great tutorial! Many thanks for the nice feedback Roger. I should have more pics and a video up at the weekend as we progress through the second layer of planking. Jase “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

|

|

|

|

|

|

|

Hi Jase Im guessing by now the copper tiling is well under way so will you be leaving the wood natural with just a varnish finish or painting her and will you be weathering the copper tiles. Regards Andy  Current builds:-C57,Zero, Lamborghini Countach, Caldercraft HMS Agamemnon,Robi,R2-D2, MFH Cobra .

|

|

|

|

|

arpurchase wrote: Hi Jase Im guessing by now the copper tiling is well under way so will you be leaving the wood natural with just a varnish finish or painting her and will you be weathering the copper tiles. Regards Andy  Hi Andy yes i am adding the copper tiles i am trying to get a hed so i can post more regularly if that makes sense i shoud be posting more on sunday Jason “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

|

|

Completing the lower hull.Once you have completed the second layer of Planking you need to decide how you are finishing your hull, as this will dictate the next preparation steps. Typically your options are Varnish, Paint or copper plate. This section with deal with paint and varnish. First thing to get clear is that preparation is a good 75% of the finished result, cutting corners will effect the end result. VarnishIf you are varnishing the hull you need to carefully sand smooth. Do not use corse abrasives no matter how tempting it is to quickly remove material. Corse abrasive will leave scratches behind that will take a long time to remove. it is better to use a medium abrasive around a 240 grit and gradually go finer to say 320 grit. Varnish, like paint, will lift the wood grain, so you will need to either lay down your chosen varnish, sand again before a final two coats; or us a sanding sealer, sand gently and apply varnish. Ideally you want a contrast between the lower and upper hull. if your model is going to be all natural wood, then the main body of the ship should be matt or satin varnish, this will look more natural. The lower hull can then be hi-gloss to show the distinction. having sanded your hull smooth apply the first layer of varnish or sanding sealer and then rub down with a 600 grit abrasive. Important note, your abrasive must be virgin so as to not drive dirt and dust into the wood which will make the varnish surface rough. remove all the sanding dust with a vacuums cleaner and then lay down your first cant of varnish. let the varnish dry and inspect the finish. You may chose to sand again with an 800 or 1000 grit abrasive to remove any imperfections in the surface. then varnish again. You can lay down the varnish with a wide flat brush or an airbrush for a finer finish. Once happy with your glass coat you may wish to to use a liquid gloss polish for a hi-shean, products such as micro-gloss are ideal for this. PaintYou may chose to paint your hull. in this case you have the option of using filler before sanding. look for a fine filler such as super filler that will fill wood grain and abrasions. The preparation of the hull is largely the same as for varnish, your aim is to have the smoothest hull possible before applying paint. Once you are happy with the filling and sanding you need to lay down the primer. A spray primer from a rattle can is a good option such as Halfords primers. if you are planning to paint the hull white then try and chose a white primer, as darker primers may show through white paint, especially if brush painting. if however you are painting the hull Copper or any other colour a grey primer will add depth to the colour. Lay a first prime and then rub down with a 1000 grit wet and dry. remove any sanding residue before a final prime. Follow the same process with the paint, lay down a first coat, sand with 1000 grit wet n dry and paint again. once the paint is dry, ideally 24 hours, you can then seal this with a varnish. Which ever way you decide to go you will have to mark out the waterline after you have sanded the hull and before you add your first preparation. I use the Amati water line tool for this job, however it is easy enough to make your own with a pencil and some rod. The instructions give you the depth of the waterline, but do refer to the plans also. In the next update we will deal with copper plating the hull in detail. “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

Rank: Super-Elite       Groups: Registered

Joined: 16/08/2010 Posts: 2,771 Points: 8,344 Location: Brighton

|

Hi Jase. Looking very nice. keep thee pictures coming Ian.   Current builds.Hachettes build the bismark,HMS Victory, HMS Hood.

Finished Builds Corel HMS Victory cross section.

|

|

|

|

|

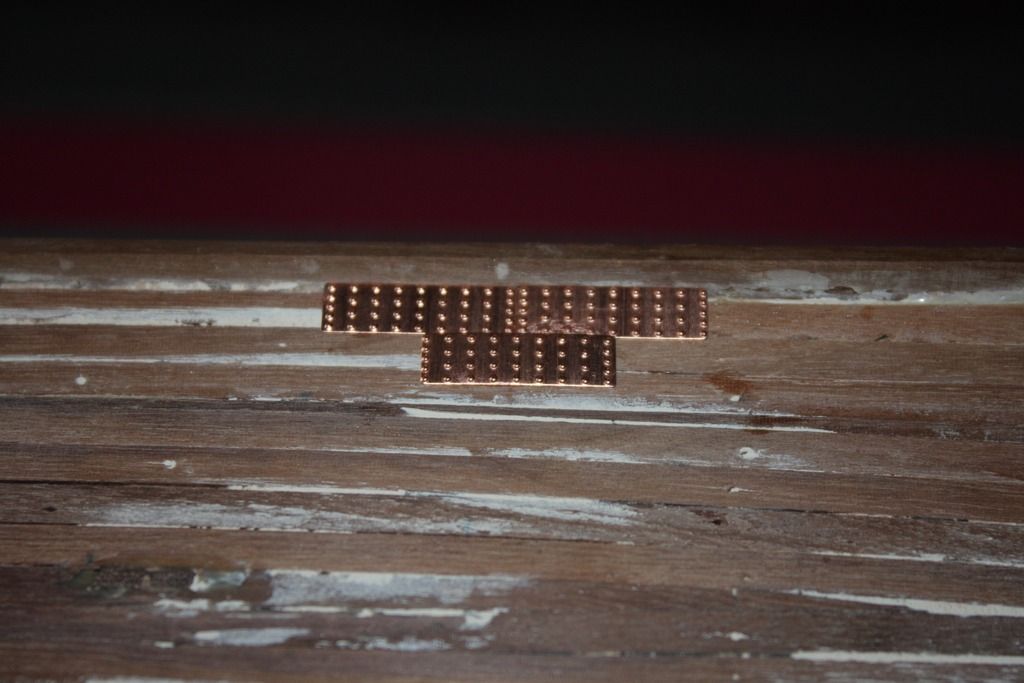

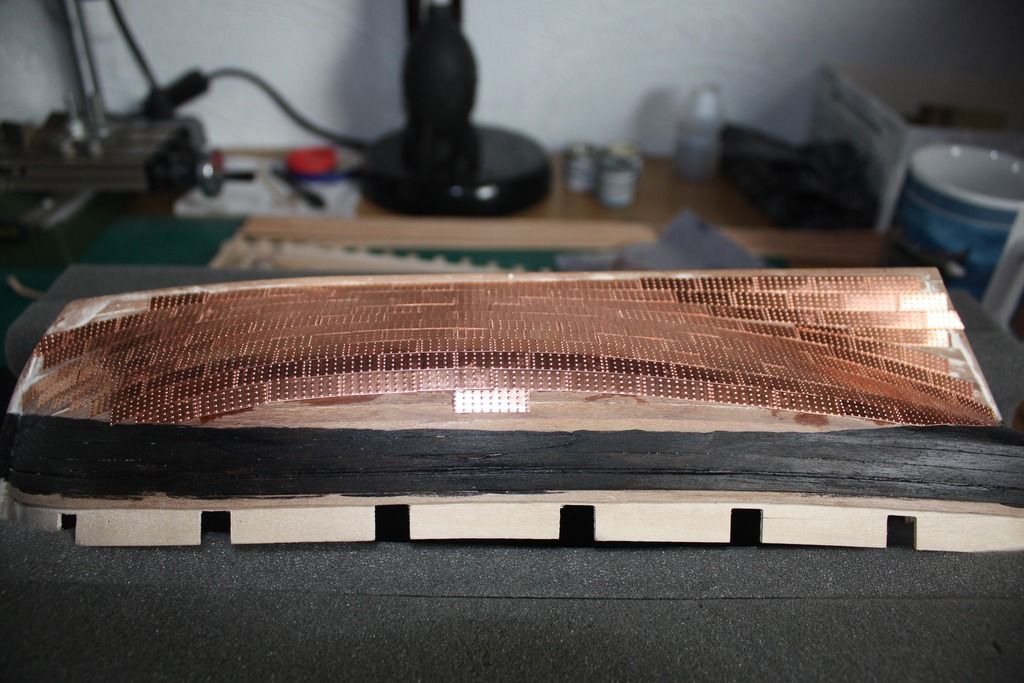

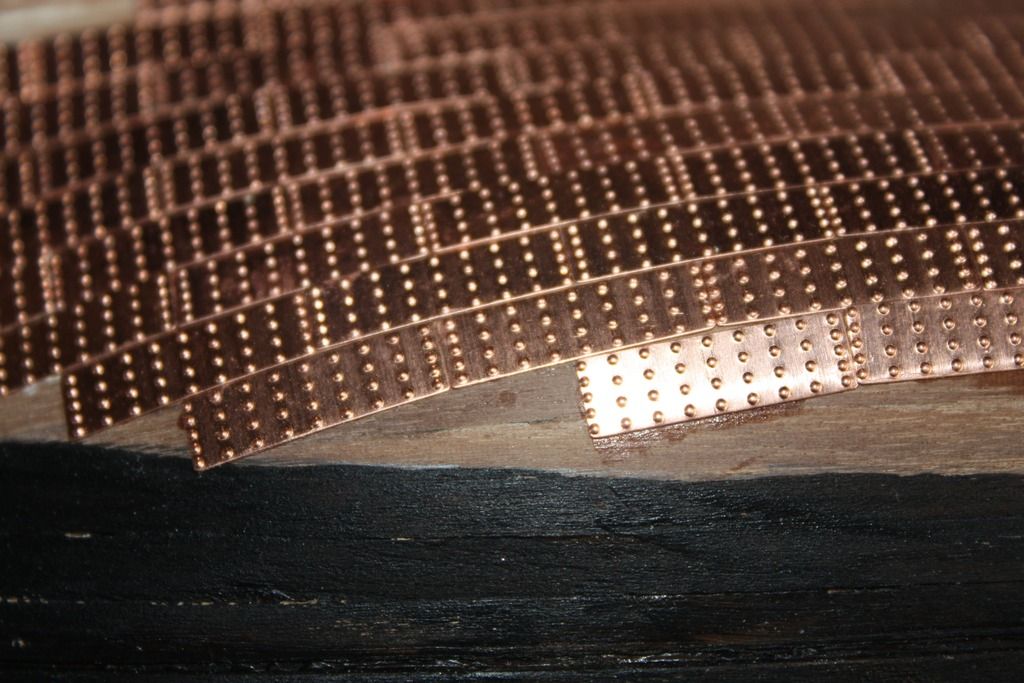

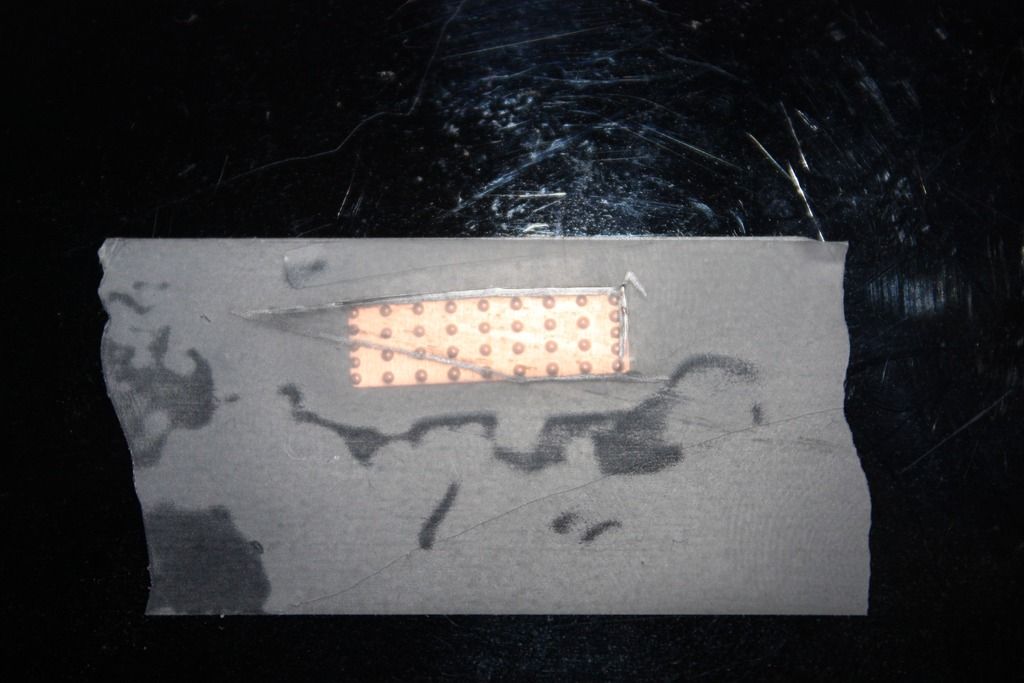

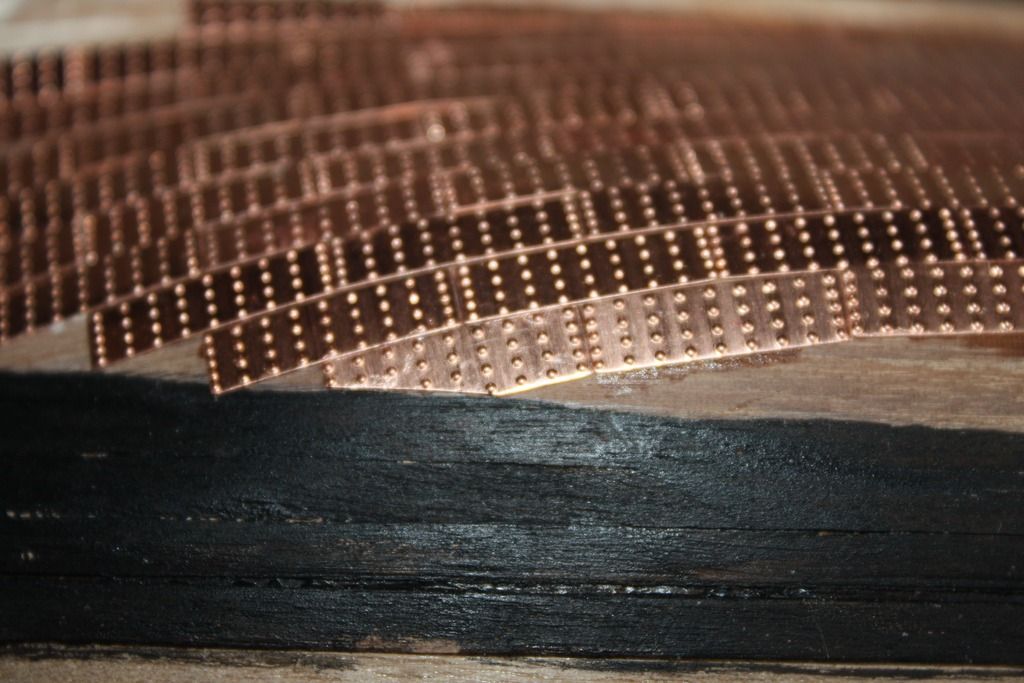

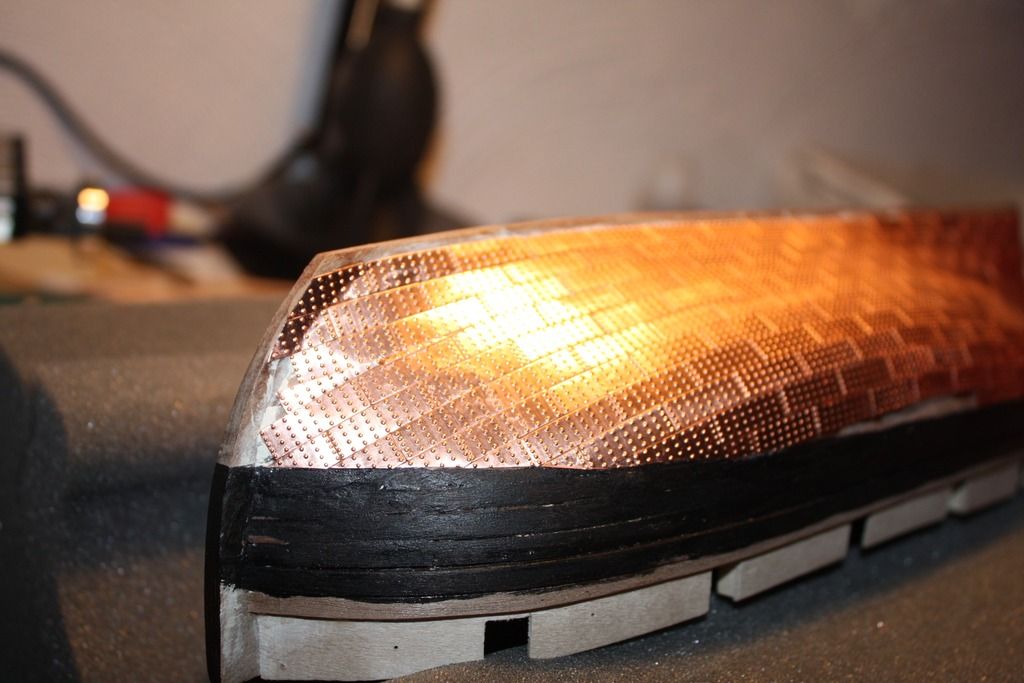

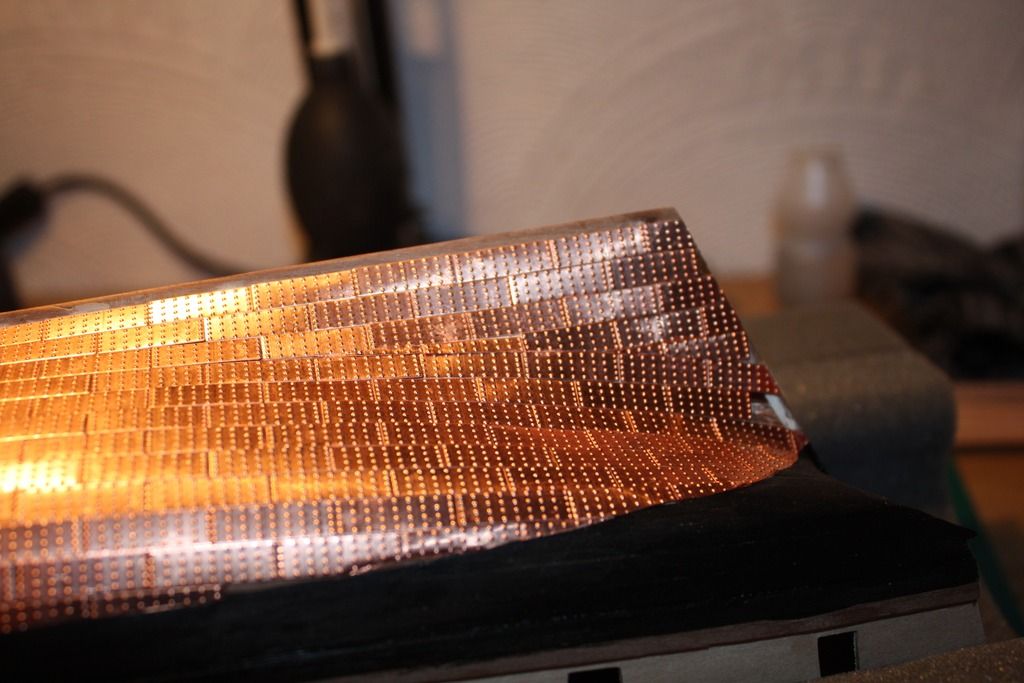

Copper platting the hull.Some model kits will give you the option to copper plate the hull, Caldercrafts Pickle is one of these kits. Applying the cooper plates can be an laborious task especially on bigger kits but the end result is well worth the effort. This is my method... First the hull prep is important, just like painting you need a smooth surface. fill any gaps in the planking and give everything a good sand smooth. Remove all the dust so you have a clean dry substriaght for the copper tiles. The next job is to mark out the waterline as described previously. I like to then paint this in as this will help later on when marking part tiles that need cutting. You can start by laying full tiles in the middle of the water line and gradually work out and towards the keel or as i prefer start from the keel and work towards the water line, which I think gives a better end result and is easier to cut the last few tiles. The kit should give you guidance on how the tiles are aligned. On Pickle each row is staggered by half the length of a tile just like laying bricks. Different model builders have different views on the best adhesive to use I have tried a number of different types and my preference is a gel CA such as Zap PT-26. I find that a gel can be decanted and left for up to 2 hours without starting to cure but will bond very quickly. Also a gel can be spread on the back of the tile with a cocktail stick easily to ensure you have adhesive evenly covering all the tile and makes a lot less mess.  Keep laying tiles filling the hull with full tiles and keeping then straight. if the shape of the hull wants the tile to start forming a banana shape let a gap begin to form, we will fill this later.  Once you have covered the hull with as many full tiles as possible we have to begin to fill the gaps. The way to do this is trace the shape needed and cut the tile to that shape. I find using a clear tape such as Scotch pressure sensitive tape works best for this job. press a piece of tape over the area that needs a cut tile and mark out the edges. You can easily cut the tile with sharp scissors or using a fresh blade in your craft knife on a hard cutting surface.        “Whenever you find yourself on the side of the majority, it is time to pause and reflect.”

-Mark Twain

|

|

|

|

Guest (9)

|